Motorsport Park Hastings

Hastings, Nebraska

BOONE, N.C. — ROSE is ready to race.

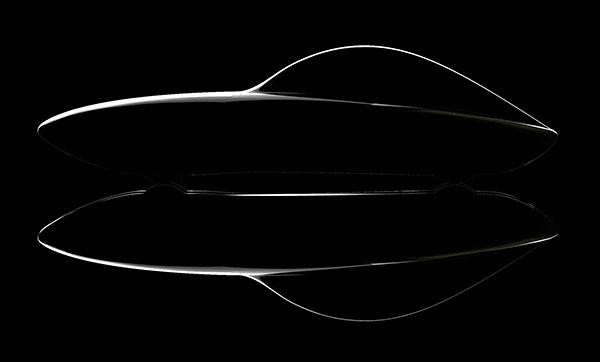

ROSE is a Cruiser Class solar vehicle — the division for solar cars that could be practical in the real world, owing to seating capacity, range, amenities and speed.

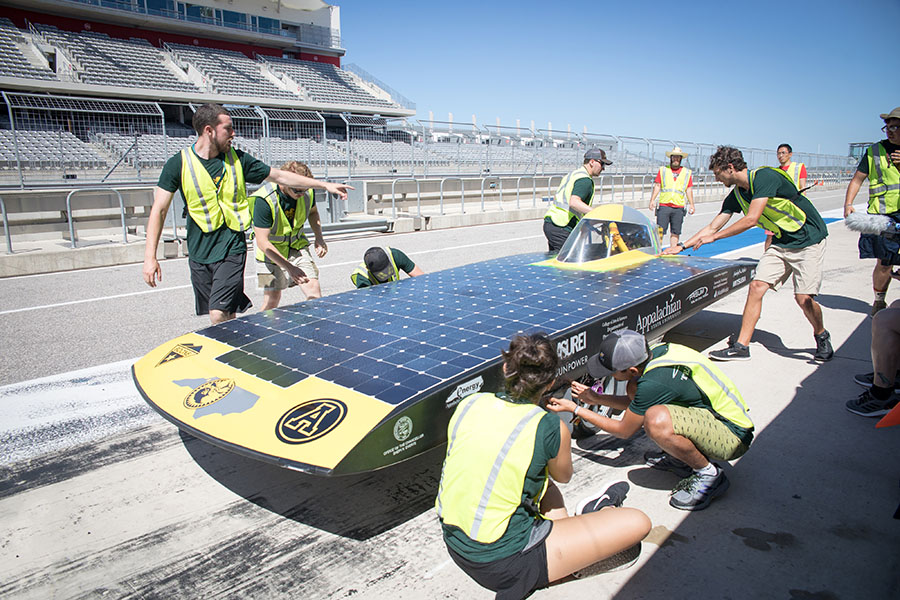

The second car built by Team Sunergy, Appalachian State University’s student-led solar vehicle team, was unveiled Friday, June 22, at the Holmes Convocation Center.

The performance of the team and ROSE — an acronym for Racing on Solar Energy — will be an indication of how well Appalachian will stack up at the 2019 World Solar Challenge in Australia. A number of telling hurdles remain — both on and off the track.

Motorsport Park Hastings

Hastings, Nebraska

In the immediate future, the team must survive back-to-back events taking place over the month of July. First up is a grueling four-day inspection called scrutineering and a subsequent race at the Formula Sun Grand Prix (FSGP) in Nebraska. Then, if ROSE qualifies, the team will compete in this year’s American Solar Challenge (ASC), which travels across the Oregon Trail. The road portion of the ASC will cover more than 1,700 miles along the trail from Nebraska to Oregon.

After almost a year of development, the team’s executive faculty director, Dan Blakeley ’15 ’18, said ROSE, and the team, are ready for the ASC.

This is not his first rodeo. Blakeley is a seasoned soldier, a U.S. Army Ranger with tours in Iraq and Afghanistan, as well as the solar car team’s founder and former student team leader. When asked about Team Sunergy’s chances at the race, he grinned and replied: “Very good. Practicality-wise and appearance-wise, we have an edge. And, when we look at the car, we say, ‘Oh, man! I’d drive that!’”

Fifteen team members and four faculty advisors, including Blakeley, will leave Boone Thursday, July 5, to begin the journey.

The first hurdle is crossing the country with ROSE in tow, arriving in time to settle in and begin the FSGP scrutineering on July 6. Nine members will travel with the car; the rest will fly to Nebraska July 5. (Details are being ironed out for the carbon offset of the team’s travel.*)

If ROSE qualifies, the team will move on to the ASC.

‘I want to build a solar-powered race car’

In the fall of 2013, former SVT advisor Chris Tolbert held a Transportations Systems class that challenged students to complete a major class project in the subject area. Having a passion for racing and sustainability, Blakeley suggested the class build a solar-powered car.

Blakeley then approached another of his professors, Dr. Jeremy Ferrell, assistant professor of sustainable technology in Appalachian’s Department of Sustainable Technology and the Built Environment. Ferrell’s area of research is biofuels, especially as related to transportation.

Ferrell explained how Blakeley sought him out: “He said, ‘I hear you have some experience in transportation.’

“I said, ‘I do — what are you interested in?’ and he said, ‘I want to build a solar-powered race car.’

“I said, ‘Well, I haven’t really done that before, but I’d love to learn about it and jump in with you.’”

That was fall of 2014.

Proven prowess in racing’s ‘brain sport’

Over the next three years, team members researched competitions and the equipment needed to compete. They wrote grant proposals. They recruited peers from across Appalachian’s majors to create a well-functioning, interdisciplinary team.

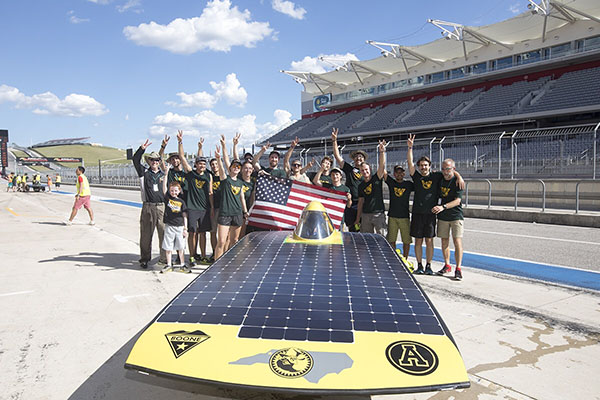

A donated shell from Iowa State University led to the team’s first competition-ready solar car, Apperion. The team competed in the 2016 Formula Sun Grand Prix and American Solar Challenge, placing third and sixth, respectively. A second-place finish in 2017’s Formula Sun Grand Prix followed.

Team Sunergy has proven its prowess on the racetrack and in engineering challenges, competing internationally in the “brain sport” of solar vehicle racing. Now, the heat is on to perform as well, if not better, in Nebraska, with an eye on racing well in Australia in 2019. Blakeley said he thinks they have the vehicle to do so.

First, he said, he has complete faith in the vehicle’s integrity. Second, he said, “We have a lot of support within the solar car community.

“Keisuke Nomura — he supplies about half of the solar motors in the solar car racing world — told us ‘I’m sending this team their weapons because their car looks like a James Bond car, an Aston Martin, and I want to be sure the winning team receives them on time!’”

Nomura is only one of a number of corporate and faculty partners who have assisted as Team Sunergy literally built ROSE from the ground up. The solar vehicle racing blogger Tony Dekker posts about the team at every race on his blog Scientific Gems and follows the team closely.

Kali Smith, the team’s operations director and a senior environmental economics and policy major from Connelly Springs, said, “We reached out to a guy about getting caps for our batteries. He literally wrote the book on building battery packs. He said, ‘Hey, did you think of this? Did you think of that?’ He wants to help us.”

The story of Appalachian State University's Team Sunergy

An informative documentary that follows Appalachian State University's Team Sunergy as they compete in the 2017 Formula Sun Grand Prix. Team Sunergy travels from Boone, North Carolina, to Austin, Texas, for three days of solar racing at the United States’ premier Formula 1 track, Circuit of the Americas.

How to grow a ROSE

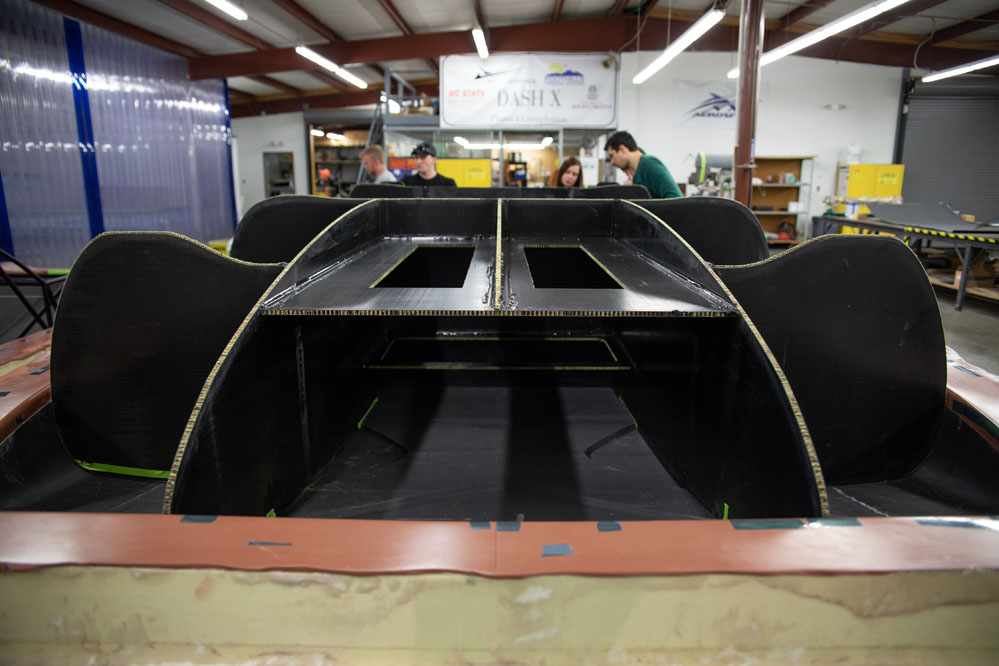

ROSE — the finishing touches applied just hours before the unveiling — was built from the ground up by the students, with not an engineer on the team.

In early 2018, Appalachian’s Chief Sustainability Officer Lee F. Ball Jr. and Blakeley were invited to Beaufort by University of North Carolina System Board of Governors member Randall “Randy” Ramsey to meet his Jarrett Bay Boatworks team.

Ramsey thought the design team at his manufacturing company might have some good advice on aerodynamics and carbon fiber. The company is a premier builder of custom sport fishing boats, has constructed over 90 unique yachts and serviced tens of thousands of vessels.

That visit led to a side trip to meet a carbon manufacturer in Little Washington — Jim Gardner — whose company, Compmillenia LLC, ultimately provided the composite seats for ROSE at a substantial discount.

Serendipitously, Gardner’s wife, Ginger — a senior editor at CompositesWorld, a trade magazine targeted to the global composites market — suggested they visit VX Aerospace.

VX Aerospace is a composites manufacturing and design company that provides composite fabrication and assembly capabilities for commercial aerospace, transportation and industrial applications. One of their projects, a Dash X drone, compactly stows inside tactical aircrafts on military missions. A bonus: The company is located in Morganton, less than 40 miles from Boone.

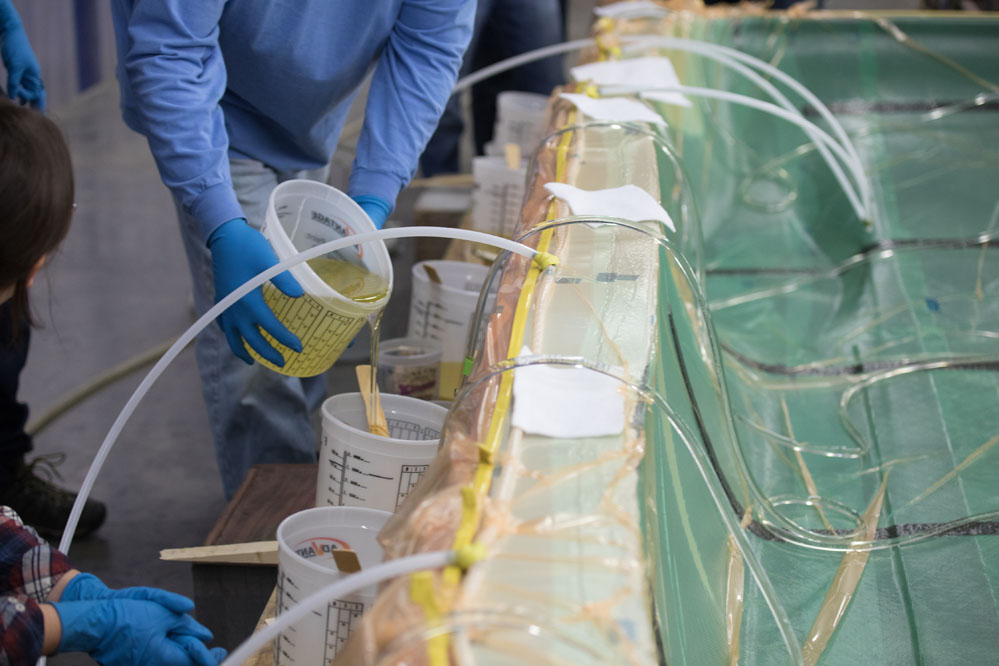

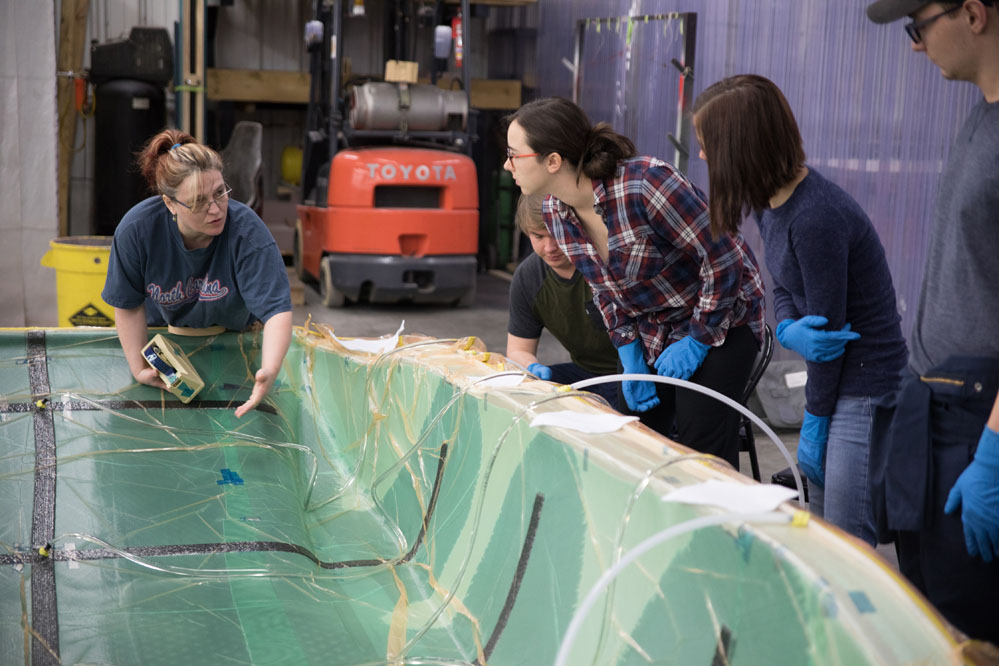

With that entrée, Team Sunergy found a building space and a team of seasoned engineers to guide them as ROSE took shape. There were stops and starts and plenty of learning moments.

For one, when it was time to match the top and bottom of the vehicle’s carbon fiber body, the team realized it had not allowed for depth in the measurements, and what was a thin line in the drawing was actually a 1/4-inch edge. Adjustments included considerable shaving of the chassis parts and fitting, and refitting before the final bond.

Another big learning moment was with crafting the windows, Smith said. The team wanted the windows formed to the shape of the car, but had no idea how to do it.

Most teams design the windows to lay flat and not curve to the shape of the car, Smith said, but, “with trial and error over many days with our team and the professionals at VX Aerospace brainstorming, we were eventually able to get just the right amount of heat to make the material, LEXAN, malleable. Now that we know that we can share with other teams!”

See some of the building processes below.

VX CEO Robert Skillen said working with the team was a very positive experience. “We enjoy working with kids. We worked with NC State and USC (University of South Carolina) and now App State. It was our first foray into coaching non-engineering students.

“This team came in with open minds, eager and hardworking. They have a positive attitude and are committed to this project. It’s apparent they are not doing it because they have to, but because it is a passion.”

Skillen also said there is definitely a place for nonengineers in a highly technical business like his. “I am drawing parts for the trucking industry now. They could fit right into that work. There are lots of opportunities. You don’t have to be a schooled engineer to participate in the composite industry.”

More than racing — it’s about the team

Early in the process, Blakeley defined Team Sunergy this way: Sun, energy, plus synergy equals Team Sunergy. “That explains us perfectly, because we have multiple majors from all over campus working towards one common goal.”

Team members brought special talents and interests to the team:

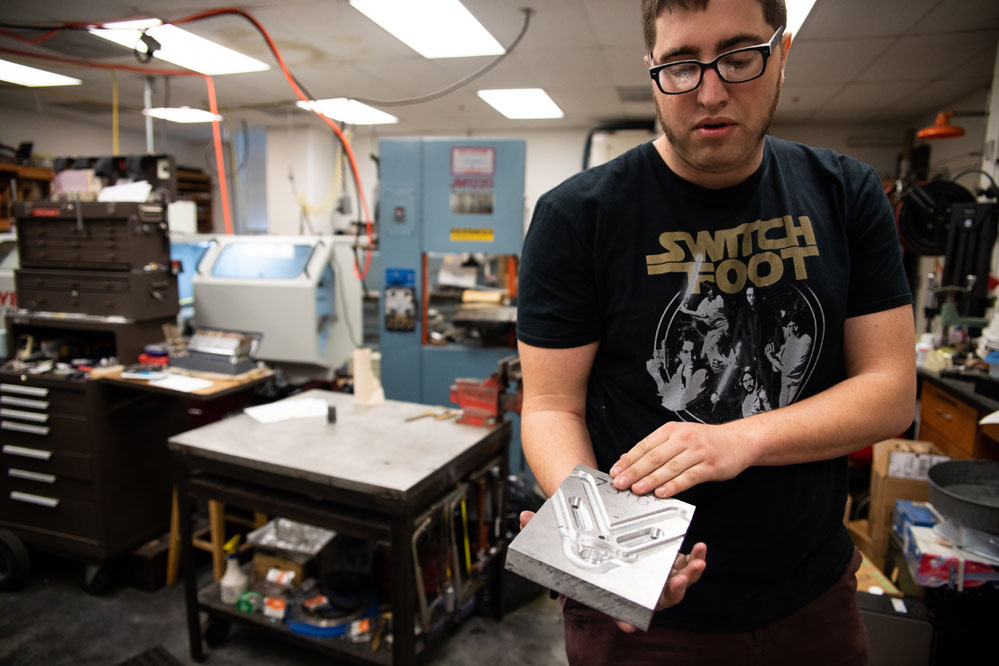

- Cody Waters, a recent graduate from Appalachian’s engineering physics master’s program, set out to design all of the suspension components for the car, from scratch, in a highly specialized software program produced by the company SolidWorks — one of the top sponsors for the team. The suspension is a highly critical part on the car that he had to design without any experience, and he got to see the process through designing, machining, installing and testing.

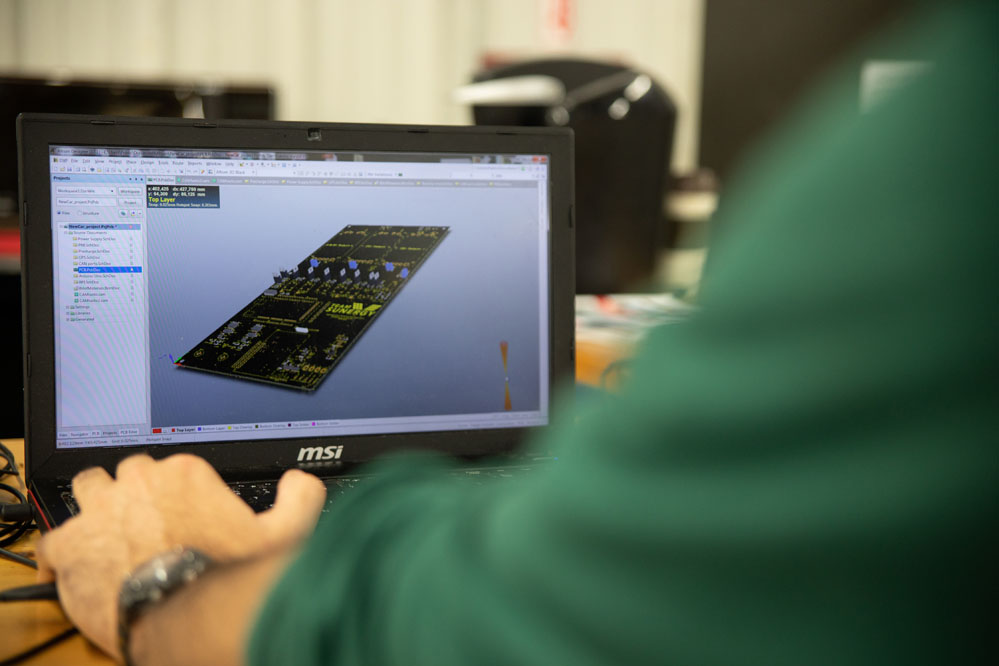

- Carlos Núñez García came to America after his wife accepted a one-year teaching position at Appalachian. He quickly joined Team Sunergy and was responsible for creating the printed circuit board for the vehicle, which serves as the brain of the car. He also assisted with the manufacturing of the carbon fiber body of the car. García returned to Spain in May.

- John Lalevee, a rising senior and industrial design major with a concentration in furniture design, began designing the body of the car just weeks after joining the team. Smith said Lalevee jumped into the role “with a fervor and learned the modeling software, Solidworks, so quickly that no one on the team was able to keep up.” Lalevee also designed the wrap on the car.

- Bree Hensley, a sophomore nutrition and foods major at Appalachian, joined the team to make a complete nutritional plan for the American Solar Challenge, to ensure that each team member had the proper intake each day to perform at peak capacity. As a former English major, she is one of the main social media coordinators for the team.

And behind the student team is, indeed, a village. In addition to VX Aerospace, which provided space, labor and mentoring, professors on campus and university leadership were also helpful. Smith was quick to say so many people touched this project that it is impossible to credit them all. Some of the players:

- Chancellor Sheri Everts has been a champion from the start, praising the team in 2016 for “work that represents the bold, confident and pioneering attitude that so perfectly represents our campus and its vision to build a brighter future.”

- Team Sunergy falls under the auspices of Appalachian’s Office of Sustainability, and Ball has been an advocate in a number of areas, introducing the team to key resources and traveling with team for competitions. Additionally, his office has provided administrative support including on-campus space for students.

- Senior Lecturer and Team Advisor Brad Johnson, Dana H. Greene, machine shop supervisor, and Mike Hughes, electronic technician, all from Appalachian’s Department of Physics and Astronomy, helped with machining and calibrating the vehicle’s suspension.

- Johnson, Ferrell and Dr. Brian Raichle, professor in and chair of Appalachian’s Department of Sustainable Technology and the Built Environment, act as faculty advisors.

- The university’s Office of General Counsel, Division of Business Affairs, University Purchasing, Physical Plant and Motor Pool have all provided guidance, labor and support in their areas of expertise.

The team is ready, Blakeley said. Like those who blazed the Oregon Trail more than 150 years ago, they are, indeed, pioneers, discovering sustainable solutions for tomorrow’s travelers.

Dan Blakeley, Linda Coutant, Megan Hayes, Alex Jansen, Chase Reynolds, Kali Smith, Jessica Stump and Derek Wycoff contributed to this story.

*As of January 2018, Team Sunergy, Appalachian State University’s lauded solar vehicle team, has offset their carbon footprint thanks to a donation of 58 metric tons of greenhouse gas (GHG) emission reductions by Sterling Planet, the sustainable energy solutions provider, and General Motors. The offsets provided were created through GM’s EV (electric vehicle) Chargepoint and EverCharge charging programs, and solar generation at their Global Technical Center. Sterling Planet calculated and confirmed the volume.

An Appalachian team seeks to change the future of transportation with a solar race car

About App State’s Team Sunergy

Appalachian State University’s internationally recognized Team Sunergy is an interdisciplinary, student-led team with a passion for sustainable transportation — and the ingenuity, innovation and drive to create it. The team began in fall 2013, as a class project to build a solar-powered golf cart, and has evolved into an award-winning program that has achieved podium finishes in every year of competition in both the Formula Sun Grand Prix and American Solar Challenge (ASC), including a first-place finish in the 2021 ASC. Both races set the standards for and test the limits of solar vehicle technology. Team Sunergy’s first vehicle, Apperion, was a modified single-occupant race car. In 2018, the team designed and built its current, two-passenger, Cruiser Class car, ROSE (Racing on Solar Energy), from the ground up. Learn more at https://sunergy.appstate.edu.

About Sustainability and Energy Management at App State

Appalachian State University’s leadership in sustainability is known nationally. The university’s holistic, three-branched approach considers sustainability economically, environmentally and equitably in relationship to the planet’s co-inhabitants. The university is an active steward of the state’s interconnected financial, cultural and natural resources and challenges students and others think critically and creatively about sustainability and what it means from the smallest individual action to the most broad-based applications. The university offers both undergraduate and graduate academic degree programs that focus on sustainability. In addition, 100 percent of Appalachian’s academic departments offer at least one sustainability course or course that includes sustainability, and all students graduate from programs that have adopted at least one sustainability learning outcome. Learn more at https://appstate.edu/sustainability.

About the Department of Sustainable Technology and the Built Environment

One of seven departments housed in the College of Fine and Applied Arts, the Department of Sustainable Technology and the Built Environment at Appalachian State University features an integrated array of programs spanning the fields of sustainable design and technology. Its mission is to foster a strong and vibrant culture of inquiry, discovery and innovation that integrates theory with application, problem seeking with problem-solving, local issues with global perspectives and technological progress with environmental stewardship. It offers bachelor’s degrees in sustainable technology and building science, and a master’s degree in technology. Learn more at https://stbe.appstate.edu.

About Appalachian State University

As a premier public institution, Appalachian State University prepares students to lead purposeful lives. App State is one of 17 campuses in the University of North Carolina System, with a national reputation for innovative teaching and opening access to a high-quality, cost-effective education. The university enrolls more than 21,000 students, has a low student-to-faculty ratio and offers more than 150 undergraduate and 80 graduate majors at its Boone and Hickory campuses and through App State Online. Learn more at https://www.appstate.edu.

What do you think?

Share your feedback on this story.

![The Search for Vertical Grasslands [alumni featured]](/_images/_posts/2026/03/vertical-grasslands-600x400.jpg)

![How NCInnovation Is Rethinking Economic Development in North Carolina [faculty featured]](/_images/_posts/2026/02/rethinking-economic-development-600x400.jpg)