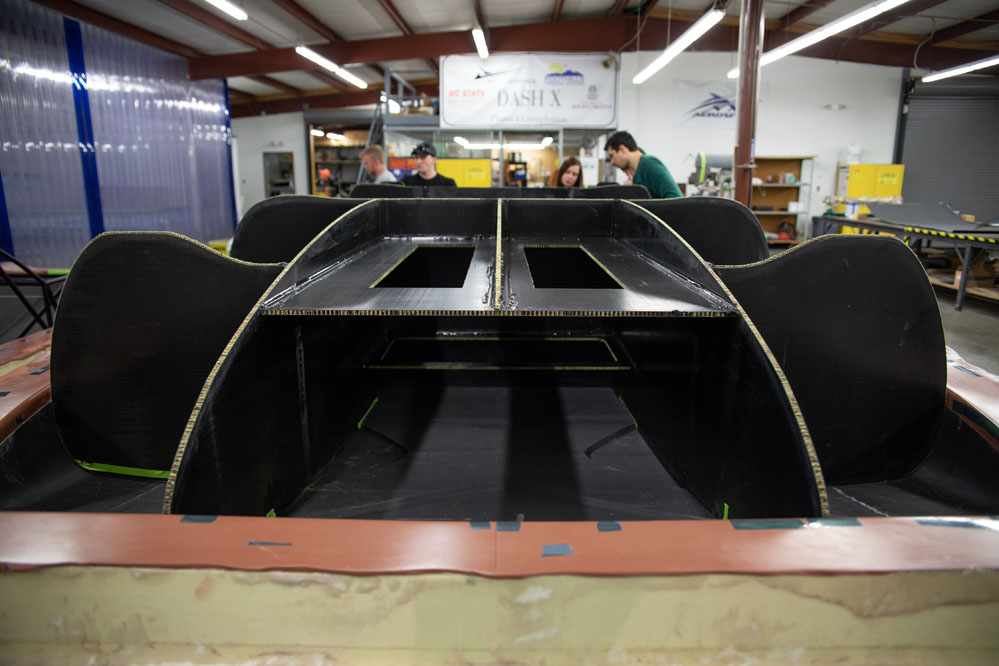

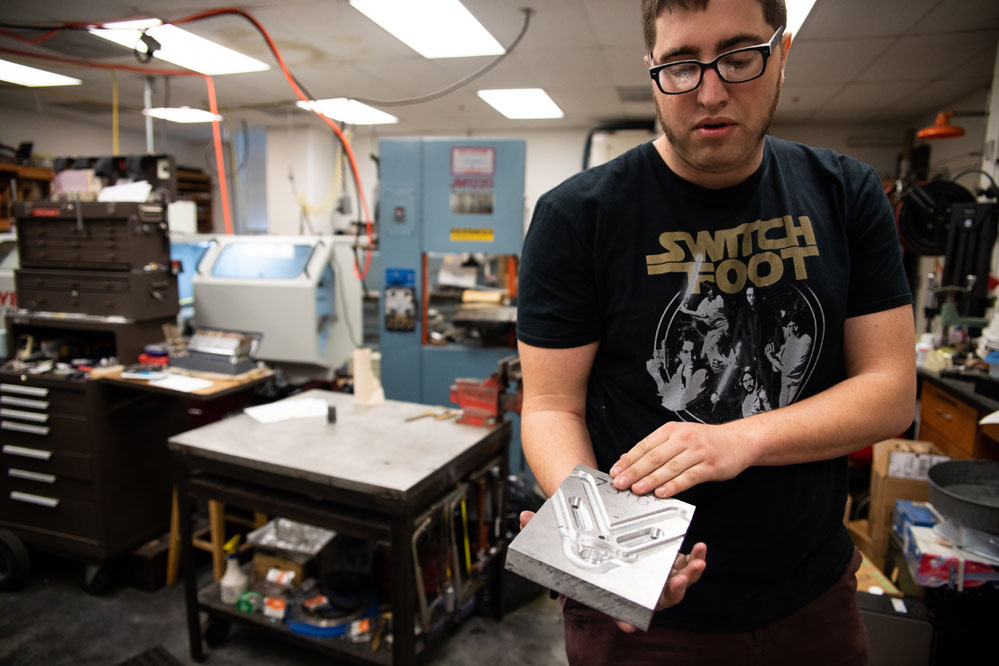

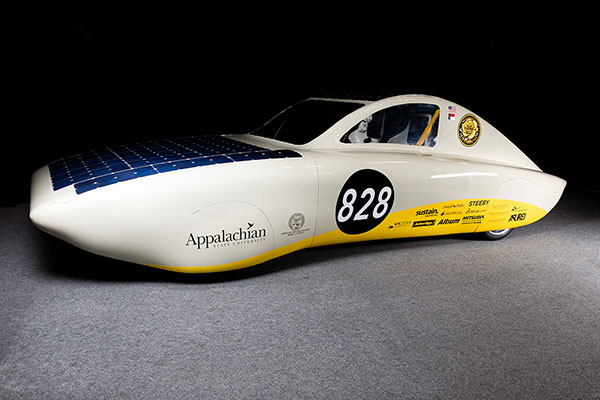

BOONE, N.C. — Appalachian State University’s solar vehicle team, Team Sunergy, designed and built its first Cruiser Class vehicle entirely in-house — including cup holders — ahead of the 2018 American Solar Challenge and Formula Sun Grand Prix.

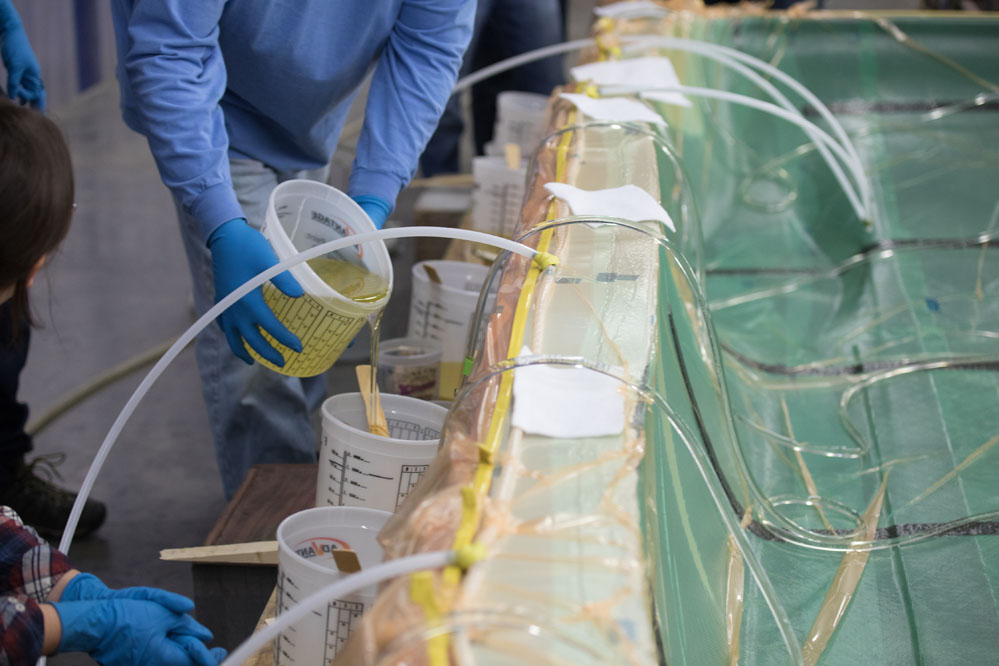

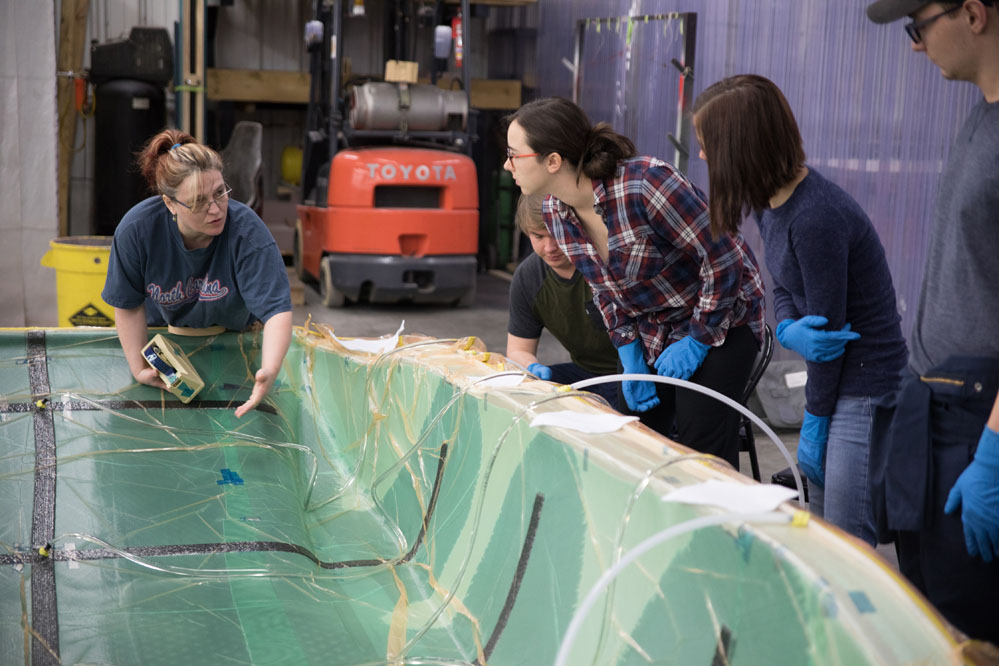

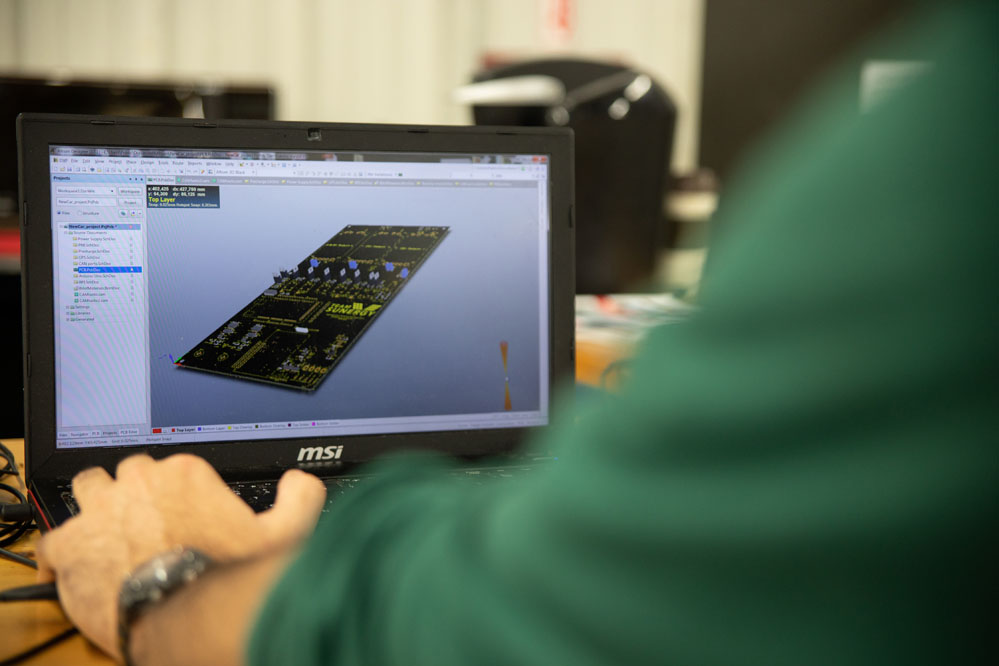

See many of the step-by-step processes required to build this vehicle named ROSE (Racing on Solar Energy).

About App State’s Team Sunergy

Appalachian State University’s internationally recognized Team Sunergy is an interdisciplinary, student-led team with a passion for sustainable transportation — and the ingenuity, innovation and drive to create it. The team began in fall 2013, as a class project to build a solar-powered golf cart, and has evolved into an award-winning program that has achieved podium finishes in every year of competition in both the Formula Sun Grand Prix and American Solar Challenge (ASC), including a first-place finish in the 2021 ASC. Both races set the standards for and test the limits of solar vehicle technology. Team Sunergy’s first vehicle, Apperion, was a modified single-occupant race car. In 2018, the team designed and built its current, two-passenger, Cruiser Class car, ROSE (Racing on Solar Energy), from the ground up. Learn more at https://sunergy.appstate.edu.

About Appalachian State University

As a premier public institution, Appalachian State University prepares students to lead purposeful lives. App State is one of 17 campuses in the University of North Carolina System, with a national reputation for innovative teaching and opening access to a high-quality, cost-effective education. The university enrolls more than 21,000 students, has a low student-to-faculty ratio and offers more than 150 undergraduate and 80 graduate majors at its Boone and Hickory campuses and through App State Online. Learn more at https://www.appstate.edu.

What do you think?

Share your feedback on this story.

![The Search for Vertical Grasslands [alumni featured]](/_images/_posts/2026/03/vertical-grasslands-600x400.jpg)

![How NCInnovation Is Rethinking Economic Development in North Carolina [faculty featured]](/_images/_posts/2026/02/rethinking-economic-development-600x400.jpg)